The art of screenprinting

|

|

The art of screenprinting

|

|

|

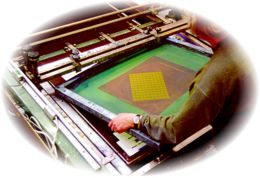

The dried screen is clamped into the master frame and located in position on the material to be printed. Each colour will have its own screen and be printed in sequence. This is why an accurate registration of each colour is crucial to the overall print. |

| Once the screen has been placed on the master frame, the squeegee - a firm rubber strip encased in a metal or wooden holder - is clamped onto the printing arm. In this case the squeegee is being fixed onto a sem-automatic screenprinting machine. |  |

|

After accurate colour-matching, the ink is poured onto the screen. A wide variety of inks is available for different materials. In some cases it may be necessary to carry out adhesion tests prior to the production run. |